AquaMaof Aquaculture Technologies Ltd. has announced that it’s 600 metric ton per annum salmon hatchery, smolt and market-size Atlantic Salmon Recirculating Aquaculture System (RAS) R&D facility has successfully grown several large batches, now ranging from eggs to Smolts to 5Kg harvest-size fish. The “Global Fish” facility, located near Warsaw, Poland, commenced operations in 2016.

"We see significant growth potential in the supply of recirculating aquaculture systems to Salmon production companies,” said David Hazut, CEO of AquaMaof. “The investment in Poland will serve two main purposes: first, we are operating this facility as an R&D center, collecting valuable information and analyzing it, for further innovation in the RAS area. Secondly, it serves as a training facility for our customers' staff.”

The Global Fish facility houses multiple RAS rearing units with tank space ranging from 1-200 m3, all under strict standard operating procedures, which maximize growth conditions for salmon.

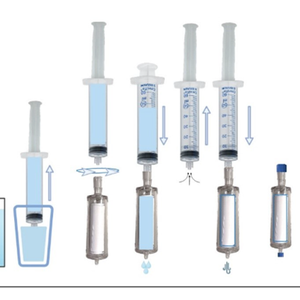

AquaMaof's advanced Zero Discharge Technology utilizes proprietary water reuse techniques. At the core of the company's RAS technology is efficient power consumption, dramatically reducing costs of energy. No antibiotics and no chemicals in the process allow for the production of healthy, natural product. Biosecurity is paramount, and complete environmental control ensures that salmon are grown in an environment that promotes the highest health and welfare status. No drum filters require minimal maintenance, while optimized feeding modes and advanced feeding management system – enable reduction of the Feed Conversion Ratio (FCR) and operational costs.

"We are extremely proud of the fact that in such short a time we were able to achieve very good results in growing smolts up to market-size Salmons, in terms of operation costs, FCR and not less important – excellent taste and color of the fish" continued Hazut.

"Apart from the Global Fish facility, we have several additional projects around the world in different stages, for Smolt and harvest-size Salmon production facilities, implementing our proprietary technology, and we expect more projects to commence in the coming months" concluded Hazut.

Two years ago AquaMaof announced it was Chosen by Grieg NL to Build the World’s Largest Indoor Salmon Aquaculture Facility in Newfoundland. The company has also established a Salmon aquaculture business unit in Scotland UK, headed by Dr Andrew C Preston.