Many aquaculture hatcheries maintain a small-scale microalgae production facility in-house for the production of live feed. Microalgae are usually grown in non-automated bubble-column systems at unknown production costs. A group of Dutch and Norwegian researchers say that other reactor systems or scenarios utilizing artificial light or sunlight and at different scales can result in more cost-efficient production processes.

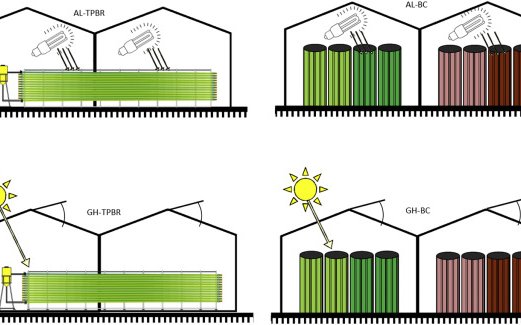

To determine the cost-price and cost-distribution of microalgae production facilities in the Dutch aquaculture industry and identify the most efficient cost-reducing strategies, the researchers performed a techno-economic analysis for small scale microalgae production facilities (25-1500 m2). Commercially available reactors commonly used in aquaculture were compared; tubular photobioreactors (TPBR) and bubble-columns (BC) in two placement possibilities; using artificial light in an indoor facility (AL) and utilizing sunlight in a greenhouse (GH) under Dutch climate conditions. Data from commercial microalgae facilities in the Netherlands were used to model reference scenarios describing the cost price of microalgae production with state-of-the-art technology in aquaculture for a biomass production capacity of 125 kg year−1.

The reference cost price for algae biomass (on the basis of dry matter) is calculated at €290 kg−1 and €329 kg−1 for tubular reactors under artificial light and a greenhouse, respectively and €587 kg−1 and €573 kg−1 for bubble-columns under artificial light and a greenhouse, respectively. The addition of more artificial light will significantly reduce production costs (by 33%) in all small-scale systems modeled.

Researchers said that the scale of a microalgae production facility has a very large impact on the cost price. With state-of-the-art technologies, a cost price reduction of 92% could be achieved by changing the scale from 25m2 to 1,500m2, resulting in a cost price of €43 kg−1, producing 3,992 kg year−1 for tubular reactors in a greenhouse.

This techno-economic model gives valuable insights in the cost price distribution of microalgae production in aquaculture. It allows research efforts to focus on the most promising cost reduction methods and optimize existing production facilities in aquaculture companies to achieve economically sustainable microalgae production for live feed in hatcheries.

Download here the study.