Scottish Sea Farms’ new RAS hatchery has achieved a critical milestone with the first smolts having gone safely out to sea pens with an average weight of 160 grams - more than double that of smolts grown by the company when using traditional hatchery methods.

Pål Tangvik, Scottish Sea Farms’ freshwater manager, said that “this is a major milestone for all of the team, not just at Barcaldine hatchery but across the company. The new hatchery has given us greater control over key factors including water quality, oxygen levels, temperature, light and speed of flow, meaning we have been able to ensure the best growing environment for the salmon. The result is bigger, more robust smolts that will be better able to withstand the natural challenges of the marine environment. We will also be able to shorten the time these salmon will spend at sea by up to two months which will reduce their exposure to these challenges and increase survival rates, and have longer fallow periods between crops which will contribute towards a safer environment for subsequent generations of fish.”

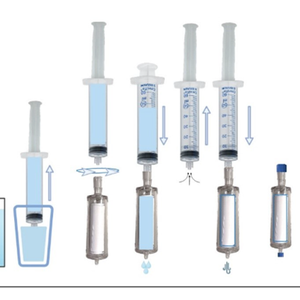

£55m Barcaldine Hatchery promises to be every bit as transformational with regards to environmental performance. Noelia Rodriguez, operations manager for the Scottish Sea Farms’ Barcaldine Hatchery, explained that “incoming water is filtered to remove any particles, then disinfected using UV light and circulated to the hatchery where it is maintained at a constant temperature of between 12-14ºC, before being cleaned again and recirculated every 20-30 minutes. This uses 98% less freshwater and significantly less energy compared with heating and cooling water at traditional hatcheries. The building uses a biomass energy system – thought to deliver the biggest CO2 savings of any renewable heat source – to provide heating and hot water, and there is provision for a hydro scheme so that we can generate even more energy in a greener way.”

The RAS facility, which includes four incubation units and four hatcheries, has taken over two years to build and is due to have its official opening in 2020.